|

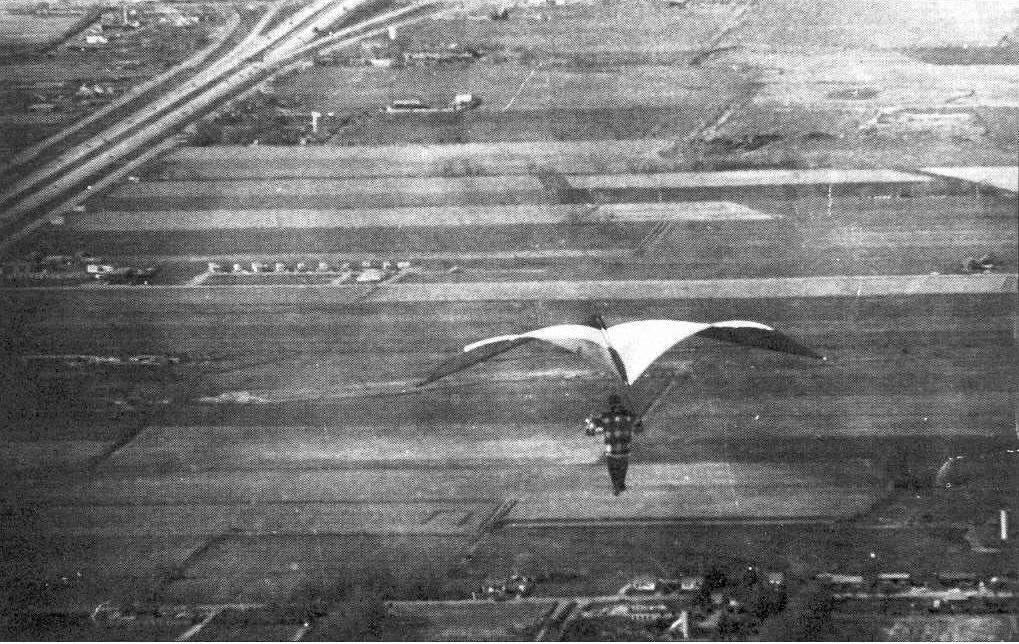

| At the age of nine (in 1958!) Dick Cheney, President of UP International built and flew the oak and nylon Rogallo wing shown above.

Also pictured is his 1973 Standard which he flew in the first Annie Green Springs Nationals. |

Dick Cheney, Aircraft Designer/Builder

(From Oak to Carbon Fiber)

© John Heiney

I consider hang glider pilots to be a special breed of the human species. Just to possess the desire to drive around the sky in a light airplane with self determination is relatively rare, and to wish to soar on natural currents using an ultralight, no-frills personal wing is the dream of a romantic. But to learn the art of hang gliding is the accomplishment of a uniquely open-minded individual.

Those in our society who follow the crowd and take no chances do not decide to hang glide. The modern hang glider pilot maintains his or her health and safety by logic, but knows that life would be boring without some risk. Helen Keller, under different circumstances would have been a hang glider pilot. In her words "security is a myth, life is either a daring adventure or nothing."

With this thought I would like to present a pilot profile of an unsung hang gliding pioneer and hero: Dick Cheney. Who first foot-launched a Rogallo-type lang glider? Most hang gliding historians credit Dave Kilbourne with the first foot-launch of a flex wing glider (a Delta Wing standard) in 1969. Dave is also credited with the first soaring flight.

But imagine for a moment a nine-year-old boy standing on a 150-foot sand hill on his grandfather's fruit ranch in Kaysville, Utah. Imagine a nine-year-old boy and his cousin building model gliders copied from a magazine photograph of a NASA Rogallo wing. Imagine a nine-year-old boy with a strong desire to fly, launching his home-made, full-scale, oak and nylon "rogallo" wing for his first airborne expenence.

Well, you need not imagine. That nine- year-old boy was Dick Cheney, President of UP International, back in 1958! Yes, that was 35 years ago, and imagination is the key word in describing Dick Cheney.

Dick is chief designer at UP, and even though his company has the planet's only true space age, high-performance flex wing (TRX), Dick is not satisfied. His design innovation spans an illustrious 23-year career of hang glider and ultralight design and manufacture, so do not be surprised at the evolutionary or revolutionary advances from this man in the future.

Dick's enthusiasm for all types of flying is equalled by his love of aeronautical and mechanical design. To Dick, it is good fun to "burn the midnight oil" while involved with his latest ideas. Before we get into new projects let us examine Dick Cheney's history in sport aviation.

Dick Cheney started flying airplanes at age 16. He soloed in seven hours (short time) when he was 17, and started flying sailplanes at age 18. He earned his private pilot's license at 22, and his sailplane license immediately thereafter. Dick remains current in airplanes and sailplanes, and works (when he can) on a side project of building an ultralight sailplane.

Afrer a long and wise diversion from his initial attempt at hang gliding, Dick's enthusiasm for pure flight was rekindled in 1970 when he built his first glider with conventional materials (aluminum and dacron) that known manufacturers were using. By 1971 his company, Parasail Gliders, was producing a Standard called the Parasail, which established Dick as a manufacturer in the early hay-days of hang gliding.

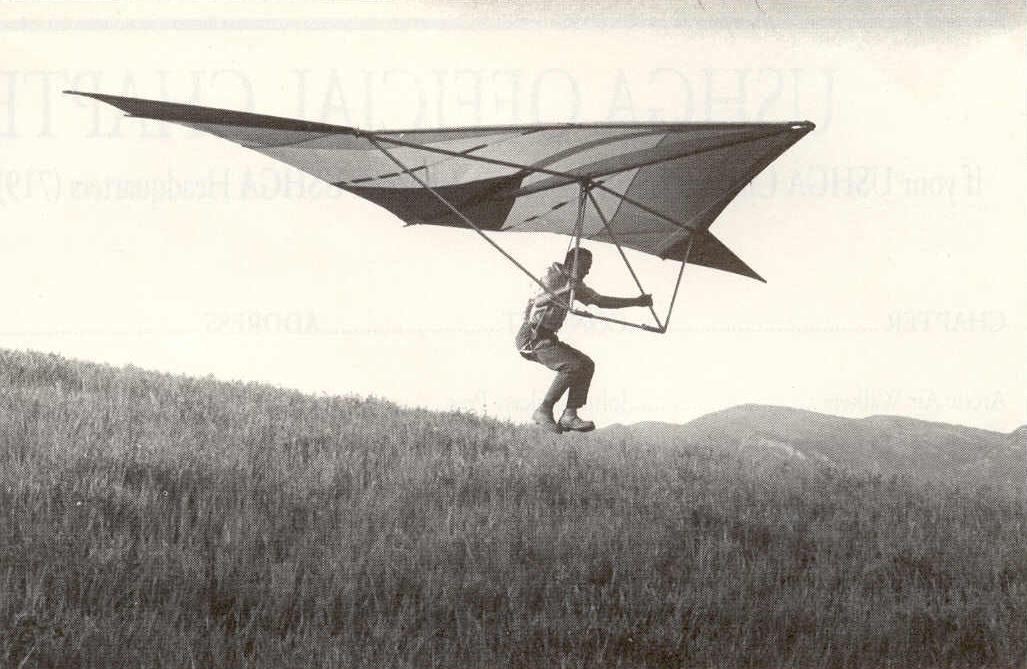

|

| Dick flying a kingpostless standard off the top of the North Side Point-of-the-Mountain in the winter of 1972. Photo by Larry Price |

Dick flew his glider in the 1973 Annie Green Springs Nationals (the first Nationals). Southern California was a hotbed for this new activity which had already become a way of life for some. Dick met some of the avant-garde flyers and manufacturers at this event.

By this time Dick had a few years of soaring experience in sailplanes, so the great disparity in controllability and safety between hang gliders and sailplanes was obvious. Hang gliders of the day were difficult to control and poor in performance and strength. Sailplanes were great for soaring and cross-country flying, and had an excellent safety record over a period of many years, but were expensive and inconvenient to transport.

But hang gliders were inexpensive, easy to transport on top of your car and required no tow-plane. A person could drive up a mountain and fly off. This was good. The natural conclusion for an innovative individual was that something in between was needed.

Two local sailplane enthusiasts named Klaus Hill and Larry Hall (of Hall Wind Meters) were thinking the same thing. They conceived a design for a glider similar to Bob Lovejoy's Quicksilver, but with a twin rudder. They asked Dick to make the sail, and when it was finished, they made the airframe to fit it.

It was called the Twin Boomer, and the tail had a large horizontal surface and two rudders that were connected to the pilot by cables. The rudders were actuated when the pilot made a roll weight-shift input.

Performance and control were improved, and the tail solved the pitch stability problem, but it was not the answer. A tail and rudders are hard to fold into a bag, and ease of foldability is a crucial aspect of a foot-launched soaring Wing.

|

| Klaus Hill flying Klaus' and Richard Miller's design which Klaus had built. Photo by Evan Hall |

Klaus Hill was a sailplane builder in Germany before emigrating to the United States. Because of the Horton Brothers' tailless wing sailplane experiments in Germany after World War I, Klaus was predisposed to the unorthodox idea of a wing with no tail to save drag, consequently increasing glide performance.

While most designers were working to improve the Standard Rogallo, several notable visionaries were looking ahead to rigid wings (Bob Trampenau, Dave Cronk, Taras Kiceniuk, Jeff Magnun, Rex Miller, Brian Porter, Craig Cato, Eric Raymond, and others I am sure deserve credit).

Klaus and Larry, who called their company Mountain Green Sailwing, decided on a tailless design for their next glider. It was a 154° nose angle wing with tip rudders for turn control and weight-shift for pitch. One of their great contributions was the unique quick and easy folding double spar airframe.

They named this glider the Fledgling because they were sure that this was the wing that would turn a great number of ground-bound humans into the much more desirable species of soaring mammal. They did regress at one point and returned to that security blanket called a tail, while they pondered the sweep/reflex factor which contributes pitch stability.

Eventually this glider evolved into the very successful Manta Fledge series of tailless rigid wings. Manta used Larry and Klaus' folding airframe design throughout the production of the Fledge. This was the glider that gave Dick his early double surface sail design experience.

Dick worked with Rex Miller of Manta on the Fledge III with which Rex won the 1979 World Hang Gliding Championships. The Fledge out-performed the flex wings so obviously that a rule change followed, putting rigid wings in a separate class. Would we all be flying rigid wings today had the rules not been changed?

Dick designed sails for four or five completely different glider designs conceived by Larry and Klaus. He found steady work in design consulting and sail manufacturing when Manta bought the Fledgling design and decided to produce it as a double surface glider.

Dick manufactured the sails for Klaus's Hummer, the first production powered ultralight (not a hang glider retrofitted with an engine). By this time Dick was building a reputation as a reliable supplier of quality sails to the rapidly growing powered ultralight industry. Klaus Hill designed and built a human-powered airplane before he died test flying another designer's powered ultralight in 1979.

In 1983 the UP Comet was the hottest glider in the world. Sales were so brisk that the UP factory in Temecula California could not keep up with the orders. UP contracted Dick to handle the overflow. Dick's growing company produced 500 Comet 165 sails in one season, in addition to the regular workload of ultralight sails.

Around 1987 the Wills Wing Sport was the industry standard, and Dick found himself making Sport and later HP-AT sails. During the most prosperous years of the hang gliding and ultralight business, Dick had 35 employees and made 24 sails per day.

Dick has made about 70 different models of sails for 25 ultralight manufacturers over the years. The current ultralight companies and a full line of UP hang gliders keep Dick busy year 'round.

In 1990 airline pilot and cross-country racer Terry Reynolds wanted to build a superior competition hang glider. His thought was the same as that many of us had already daydreamed about. "If I could build a hang glider frame out of the finest material available, what would I use?" The obvious answer? Carbon fiber composite.

After some initial work with the frame, Terry needed an innovative sail to match the innovative airframe. Dick Cheney had the knowledge, and Tony Barton and Mitch McA1eer contributed to the project as well. Salt Lake City happened to be a Mecca of carbon fiber research and manufacture, so all of the highest quality elements came together at one place at one time.

The rest is hang gliding history. In 1991 Tony Barton won the U.S. National Championships on the awesome TRX flying against the other U.S. world team pilots who were backed by major manufacturers. Tony, who was one of the few serious competition pilots who was willing to risk his professional career on a unproven glider, went on to win the Hobbs X-C Meet and several other contests over the next two years. In addition, the TRX was the 1991 and 1992 World Aerobatics Championship glider.

Dick knew that a great performing competition glider that was difficult to fly would not do the hang gliding community any good, so he kept this thought in mind throughout the design project. The result was a glider that performs at least as well as any high performance wing on the market today, weighs less and possesses probably the best combination of sweet handling and ease of landing in an all-out performance hang glider.

While some pilots were reluctant to commit to an "unproven material," Dick knew that carbon fiber had stood the test of time in many aviation and other applications. The Voyager, which Dick Rutan and Jeana Yager flew around the world in nine days without refueling, has carbon fiber wing spars made in Salt Lake City. The F- 117 A Stealth Fighter uses structural carbon fiber. The new V-22 Navy Tilt-Rotor VTOL transport is 80% carbon fiber by weight.

After three years of service the TRX has an excellent safety record; moreover, the idea of replacing a "timed-out" sail and retaining the composite airframe looks viable. In fact, the glider that U.S. World Team member Tony Barton won day five with at the recent World Hang Gliding Championships had a new sail on his last competition glider's air- frame.

The savings would be considerable if only one sail replacement were made, and it might turn out that two, three or more sail replacements will be no problem for the original airframe. This would be revolution- ary from a pilot pocketbook standpoint.

The latest feather in Dick Cheney's cap is a UP team win at the Manufacturer's League Meet at Dinosaur. The new upgraded version of the TRX won four of the top five places: Dave Sharp, first; Tony Barton, second; Butch Peachy, fourth; and Dave Seaberg, fifth.

The new UP carbon fiber tandem glider is another industry first, but it is nothing compared to what Dick Cheney has in his mind for the future of hang gliding. As usual, Dick is working on a new design at this moment. Do not expect it to be out soon, but do expect it ot be cutting-edge.

Published in October 1993 HANG GLIDING Magazine